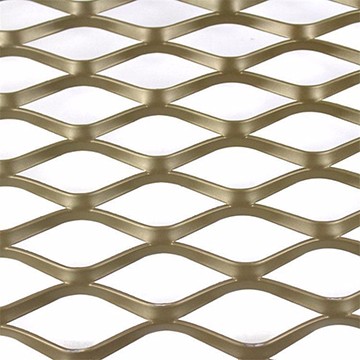

100x40mm Diamond Hole Expanded Metal

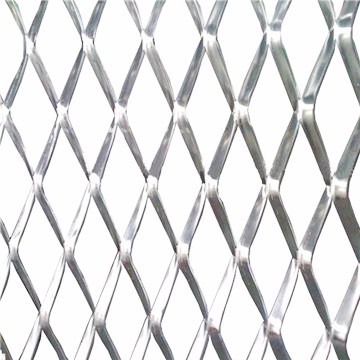

80x32mm Diamond Hole Expanded Metal

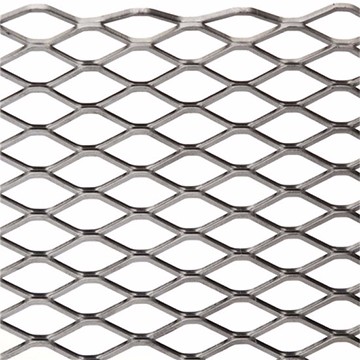

60x22mm Diamond Hole Expanded Metal

50x25mm Diamond Hole Expanded Metal

40x20mm Diamond Hole Expanded Metal

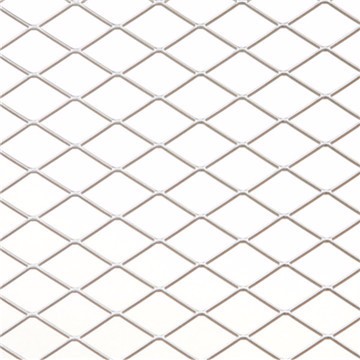

25x12mm Diamond Hole Expanded Metal

12x8mm Diamond Hole Expanded Metal

8x4mm Diamond Hole Expanded Metal

4x2.5mm Diamond Hole Expanded Metal

1.5x0.8mm Diamond Hole Expanded Metal

Battery Current Collector

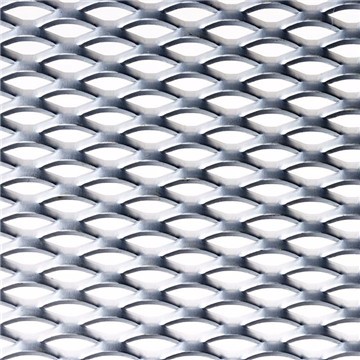

Interduction

The electrically active material comprising the electrodes of most modern battery designs are powders, slurries and laminates and require a mechanical support structure to hold them in place during the manufacturing process.

This support structure also functions as a current collector and provides the electrical connection point for the external circuit.

Current collectors of thin film batteries must be flexible, have high surface area, be cost-effective, and allow fluids to flow through them.

Our expanded metal fits all these requirements and it is micro-permeable by design, therefore it allows the transport of the protons from the anode to the cathode through the membrane.

It also forces the electrons to travel around a conductive path to the cathode, functioning as a key component in battery manufacturing.

The expanded metal is manufactured in slit coils or sheets and is processed as discs or most any shape as required.

We have been providing expanded metal for battery industry for 10 years. The common materials include stainless steel, nickel, aluminum, and copper etc.

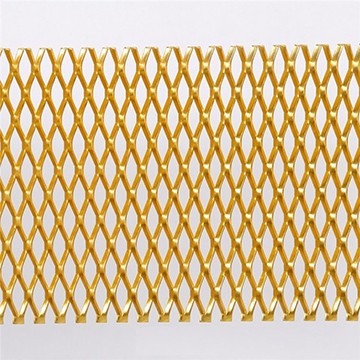

The common sizes

Plate thickness: 0.3mm, 0.4mm, 0.5mm

Hole size:0.5X1mm, 0.6X1.2mm, 0.8X1.6mm, 1X2mm, 1.25X2.5mm, 1.5X2mm, 1.5X3mm, 2X2.5mm, 2X3mm, 2X4mm, 3X5mm, 3X6mm, 4X8mm, 5X10mm, 6X12mm, 7X14mm, 8X16mm, 10X20mm, 15X30mm, 20X40mm.

Add: The East Zone Development Industry, Hebei, China 0086-311-89255081

zhao@webwirecloth.com

Support:NINEWIN INTERACTION