Choosing The Perforated Metal Right Hole Shapes

The types of hole shapes in perforated metals is limited by the technological ability to machine the cutting dies into a specific shape and withstand the stresses of the punching process.

The most commonly produced hole shapes are:

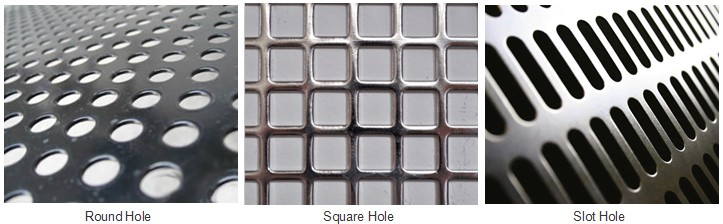

Round Hole

Round hole is the easiest and most economical shape for perforated sheet. Round holes are used in many industries, including filtration, shielding, battery,architecture etc.

Square Hole

Square holes are able to provide a large amount of open area, also providing a strong barrier used to resist impact loads.

As the tendency of the punches to suffer increased stresses near the corners of the square shape, increased wear on equipment occurs during the square hole perforation process.

So square hole increases the production cost over round holes.

Slot Hole

Slot holes consist of long rectangles with a half-circle or square ends. They are used for screening and sorting materials, such as seeds and grains.

According to user need, the slots can be parallel to either the width or the length of the sheet .

Add: The East Zone Development Industry, Hebei, China 0086-311-89255081

zhao@webwirecloth.com

Support:NINEWIN INTERACTION